3D design – the integrated CAD CAM solution

3D design opens the door to a new dimension in patient treatment. The intelligent, integrated CAD process solution digitalises your treatment processes, making the production of the subsequent orthopaedic devices easy, fast and clean – with no additional annual licence or follow-up costs.

3D design opens the door to a new dimension in patient treatment. The intelligent, integrated CAD process solution digitalises your treatment processes, making the production of the subsequent orthopaedic devices easy, fast and clean – with no additional annual licence or follow-up costs.

Digital treatment for any application

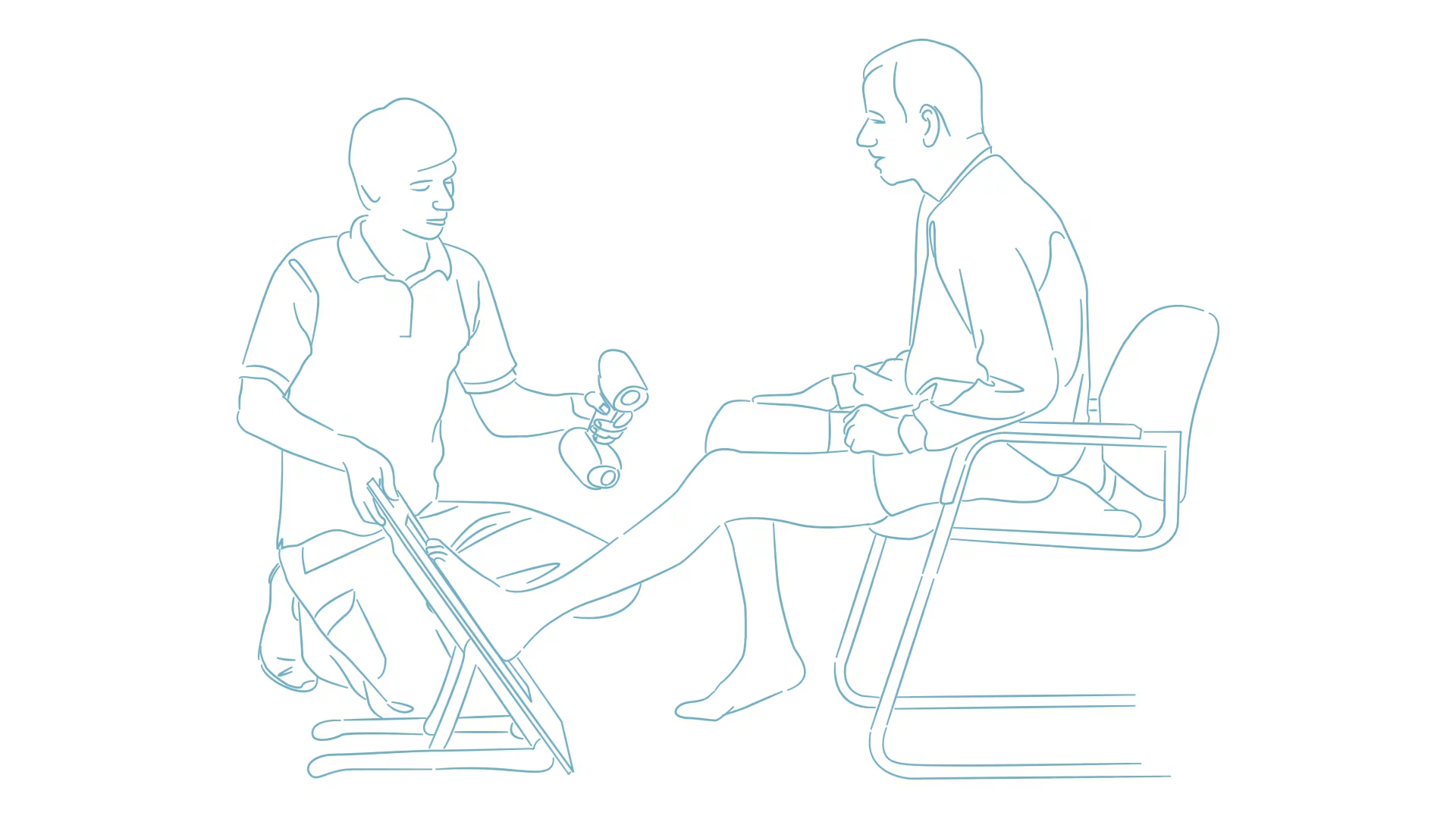

When you choose 3D design, you get a comprehensive kit consisting of a 3D scanner, CAD software, and above all, valuable support – with no additional annual licence or follow-up costs.

That being said, a system is only ever as good as its users. For this reason, the team here at Ottobock places a special focus on providing you with not just an excellent product but also with intensive training on how to operate and use it.

Advantages at a glance

Orthotics products

Prosthetics products

Additional digital solutions

TF Design

TF Design is a free software solution for designing customised check sockets, helping you complete your fittings quickly, easily, efficiently and in high quality. TF Design is an outstanding alternative to the conventional plaster cast technique, offering a host of benefits for you and your patients.

TF Design is a free software solution for designing customised check sockets, helping you complete your fittings quickly, easily, efficiently and in high quality. TF Design is an outstanding alternative to the conventional plaster cast technique, offering a host of benefits for you and your patients.

iFab EasyScan

iFab EasyScan makes it easy to start digitalising workflows in orthopaedic technology.

iFab EasyScan makes it easy to start digitalising workflows in orthopaedic technology.

총 2개 중 2개의 결과