MyFit TT/TF.

Ottobock’s MyFit TT/TF offers definitive 3D-printed transtibial and transfemoral sockets, fabricated through a fully digital process at our Salt Lake City facility.

Ottobock’s MyFit TT/TF offers definitive 3D-printed transtibial and transfemoral sockets, fabricated through a fully digital process at our Salt Lake City facility.

MyFit TT.

These lightweight, strong, and precise sockets are made using a multi-jet fusion 3D printer with nylon plastic (PA12). The unique support structure allows the socket to support up to 275 lbs. while maintaining a low-profile proximal wall thickness of 3 mm. This results in a durable, carbon fiber-like socket without the complexity of traditional fabrication.

3D printing enables custom features, such as built-in recesses for different suspension methods, creating a flush fit and improved cosmetic appearance.

MyFit TT also allows for up to 15 degrees of socket flexion and can offset the distal attachment up to 25mm, reducing weight and providing a smooth transition to the distal attachment.

Patient Selection

MyFit TT is suitable for transtibial patients with mobility levels from K1 to K4, especially those with stable limb volume requiring pin, suction, or vacuum suspension.

Contraindications

Post-operative edema or uncontrolled volume fluctuations

Short residual limb (< 10 cm from MTP to limb end)

Long residual limb (> ¾ of the length of the sound limb)

Want to Learn More?

To get the most out of MyFit TT 3D-printed sockets, we recommend checking out our MyFit TT 3D Printed Socket Product Essentials course. It’s a great way to get familiar with the process and ensure the best results. You can find the course on our eLearning platform at myLearning.

How to Order MyFit TT or Check Socket.

- Create an ICC iFab customer account

- Take an optimal scan of the patient’s residual limb

- Choose TT and select either a 3D printed socket or plastic check socket

- Fill in all order details

- Upload the scan from Ottobock’s EasyScan app or another accepted format (STL, PLY, OBJ)

- Ensure all modifications suit the patient’s needs

- Select the appropriate suspension method

- Submit your order

MyFit TF: Transfemoral Diagnostic Sockets.

MyFit TF is a web-based software within the iFab Customer Center (iCC) that allows prosthetists to create and order transfemoral check (diagnostic) sockets using just a few simple measurements. MyFit TF replaces the highly successful TF Design program that has been in use for the past 25 years.

The advantage of MyFit TF is its ability to digitally edit and visualize adjustments for the check socket. This removes the time-consuming process of casting, plaster modifications, and fabrication. MyFit TF offers extensive modification options to customize the socket to a patient's specific needs and improve the overall fit. Prosthetists can adjust reduction values, socket brims, and create build-ups to optimize fit.

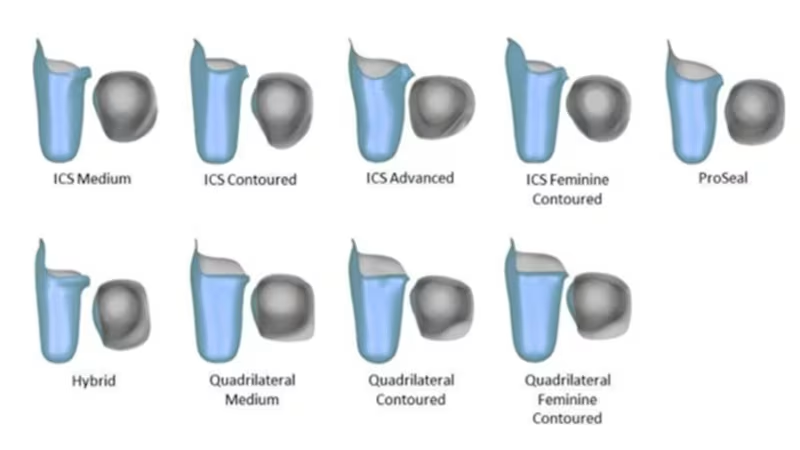

Socket Shapes: MyFit TF offers 9 different socket shapes, including 6 ischial containment and 3 quadrilateral shapes, to provide varying levels of support and contouring for different patient needs.

Suspension Options: Prosthetists can choose from suction, locking, or vacuum suspension methods, which can be paired with any socket shape. These suspension options can be used with or without a liner.

Want to Learn More?

To get the most out of MyFit TF and understand all the customization options, we recommend completing the MyFit TF eLearning Course on myLearning. The course provides in-depth knowledge of the MyFit TF process and how to create well-fitting check sockets for your patients.

What You’ll Need to Order a MyFit TF Socket

Measurement Tool Kit

The MyFit TF measurement tool kit (743R13) helps obtain accurate measurements for consistent results. At a minimum, the 743S10 tool for length measurements is recommended.Submit the Socket for Fabrication

Use the Ottobock iFab Customer Center (iCC) to enter patient data, create the socket, make any necessary modifications, and submit it for fabrication.